Your advantages of light optimization

Why you will

profit

enormously

DIN EN 12464

Your company must meet

these requirements

Expert tip

Universal lighting is not suitable for your woodworking store. We recommend a flexible lighting concept consisting of individual solutions for each workplace and each activity. Our lighting experts will calculate for you individually what such a solution would look like for you.

Your time

is valuable.

You have everything for your light optimization but it remains a time expenditure, which you can use better elsewhere?

|

| |

|---|---|---|

|

|

★★★★★

"WATT24 scored with us with excellent service and know-how! Anytime again"

- Max Kaiser from Lippstadt

Why searching for so long?

Concentrate on your business, your lighting expert will calculate the optimal combination of devices for you.

So simple.

- placement recommendations

- product recommendations

- standard-copmliant lighting

- individual ideas

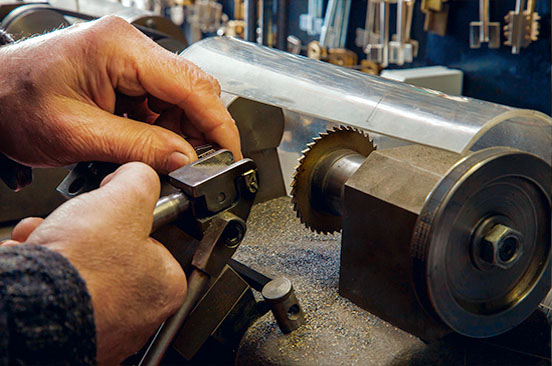

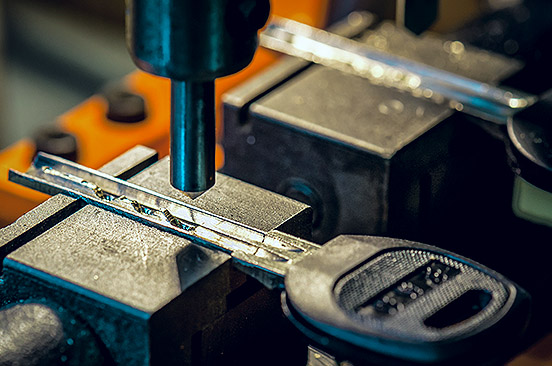

What are the legal requirements for locksmith lighting?

The illuminance, measured in "lux", is prescribed by law for most commercial areas of application. Different lux values apply for different areas of activity. The specified values refer to the amount of light that reaches the floor. Thus, they have an influence on how much light must be installed on the ceiling.

- Tool, jig and fixture making, precision and micromechanics: 1000 lux, CRI 80

- Very fine assembly work: 750 lux, CRI 80

- Electroplating; welding: 300 lux, CRI 80

- Forging Casting and melting shops, emptying shops, machine molding: 200 Lux, CRI 60

- Machine work: 300 - 500 lux, CRI 60

- Marking, inspection: 300 lux, CRI 60

- Wire and tube drawing shop, cold forming: 750 Lux, CRI 60

- Sheet metal processing: 200 - 300 lux, CRI 60

- Production of tools and cutlery: 300 Lux, CRI 60

Is it worthwhile to rely on LED lighting for metalworking companies?

Modern LED lighting is worthwhile not only because of its energy efficiency. LED lights have a long service life, so there are no costs for frequent maintenance or replacement of lighting components. We are happy to help with the conversion!

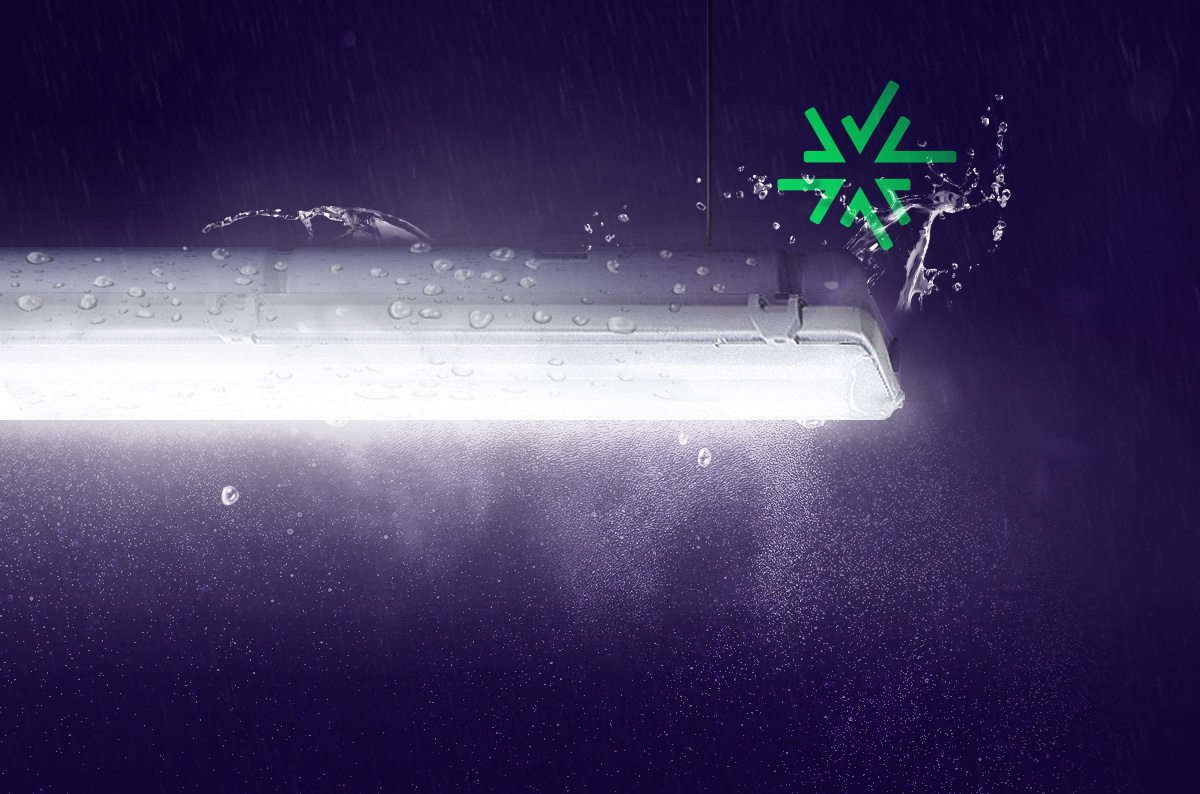

What IP protection do the lights in my locksmith shop need?

The protection factor of the luminaires is of great importance in metalworking plants. Due to the occurrence of dust, sparks and moisture, the luminaires should be equipped with IP protection of ≥ IP54, so dust and splash water cannot harm them.

What else do I need to consider when lighting my locksmith shop?

Luminaires used in workshops must not dazzle under any circumstances, because this is not only perceived as annoying, but can also lead to massive hazards, especially when working with machines. Glare can be prevented by specially developed optics; but the mounting height and angle are also important prerequisites for safe working. To identify which luminaires cause more or less glare, the degree of glare is measured in the so-called UGR value.